Comprehensive PV System Inspections

- Staff of multiple Electrical and Mechanical Engineers engaged in all O&M activities

- Technically skilled personnel inspect, identify and implement action plans for both preventive and corrective maintenance

- Mechanically inspect all BOS equipment for failures or non-conformance issues

- Inspect modules and racking to identify any failures or damages

- Inspect site for vegetation, pest or erosion issues

- Comprehensive report with photos and prioritized list of non-conformance items

|

|

|

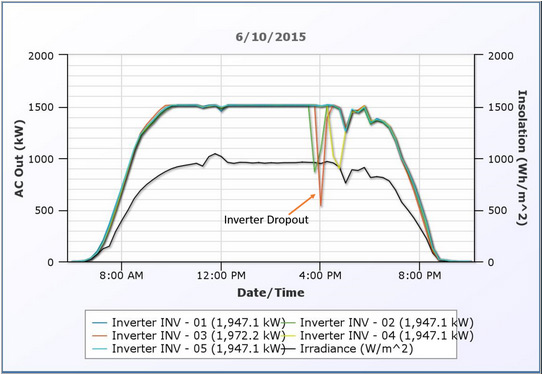

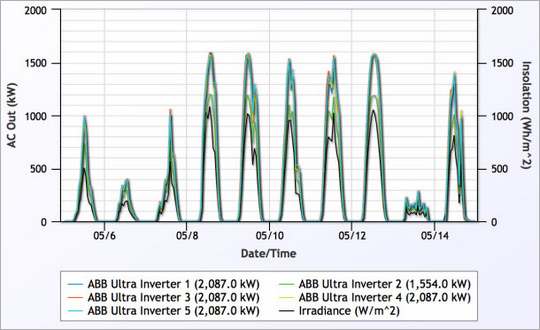

PV System Monitoring

- 24/7 monitoring of PV system, inverter and combiner level performance

- Substantial experience managing portfolios with multiple monitoring solutions

- Real-time inverter graphing from monitoring to identify outages or issues often prior to monitoring alerts being generate

- Alert recognition, analysis and action plans to minimize false alarms

- Gatekeeper role to maximize production and system ROI while minimizing O&M expenditures

- Highly qualified engineers to analyze alerts/alarms/faults

- Detailed understanding of both PV and inverter operations

- Comprehensive processing of complex inverter and performance data to determine root cause of production issues

|

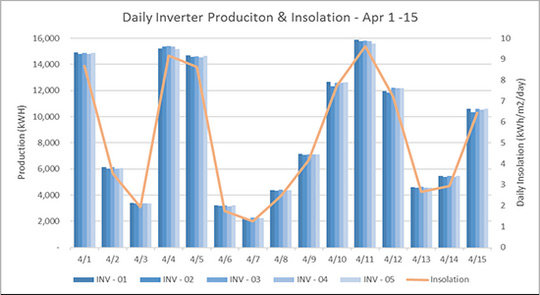

System Performance Analysis & Reporting

- Engineering-grade analytics; identify performance variation via inverter/combiner/string comparative analytics

- Analysis of system/inverter performance against weather adjusted performance metrics

- Document known production loss issues, identify underperformance issues and provide actionable plans to investigate and resolve issues

- Variety of reporting frequencies from daily/monthly/annually

- Monthly PPA Invoicing and Meter Audit/Verification Available

|

|

|

Preventative Maintenance

- Ensure equipment reliability and validity of manufacturer warranty

- Perform manufacturer recommended preventative maintenance on all equipment ensuring both equipment reliability and validity of manufacturer warranty

- Central and String Inverters

- Combiners/Recombiners

- Transformers/Switchgear

- DAS/ Monitoring Equipment

|

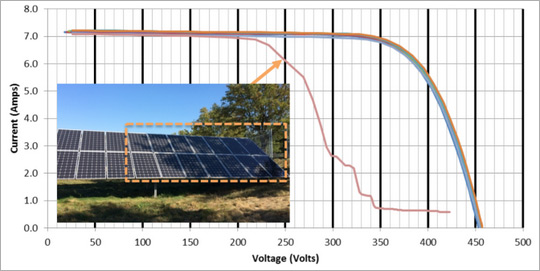

Electrical Testing and Servicing

- IV Curve Tracing & Analysis

- String Level Open Circuit and Operating Current Verification

- Identification of issues, production impact and corrective action plans

- Over 500MW of IV Curve Tracing experience with engineering quality analysis

|

|

|

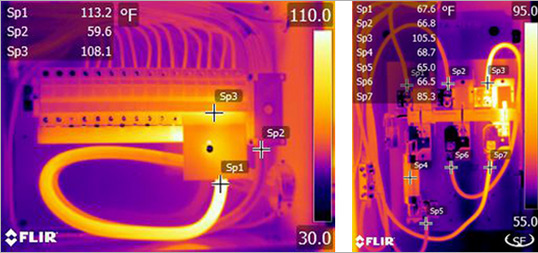

Thermal Imaging

- Thermal scans of PV equipment including all field terminations

- Non-contact verification of adequate torque

- Staff of Certified Level 1 Thermographers

|

Warranty Enforcement

- Make and coordinate claims under available warranties from manufacturers or installers

- Maintain relationships with manufacturers to enable timely reconciliation of equipment failures

- Focused on restoring production and minimizing losses

|

|

|

Maintenance Logs & Service Tickets

- Maintain historical data, performance history and logs of service/repair tickets

- Identify trends and provide corrective action prior to catastrophic failures

- Historical analysis of equipment issues and failures provides insight into future equipment selection and O&M staffing requirements

|